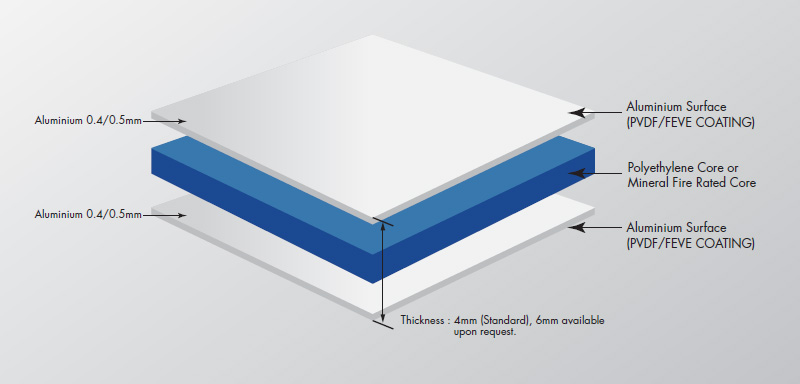

Vitally Aluminium Composite Panel is a aluminium composite material and sandwich-type composite panel comprises of a non-toxic polyethylene plastic core firmly bonded between two aluminium sheet. Surface of the aluminium sheet is coated with fine powdergrade–KYNAR 500 PVDF or option with FEVE resin for better high gloss quality.

Its robust structure of layered metal and polymer core offers extreme toughness. The smooth and uniform aluminium surface with color coating is definitely visually appealing. Both PVDF resin coating or FEVE resin coating on the surface of aluminium composite material enhance its resistance to weather and corrosion. It is ideal for internal and external used.

| Specification | ||

| Standard | Customize | |

| Panel Thickness | 4mm | ≤ 6mm |

| Aluminium Thickness | 0.4mm | 0.5mm |

| Panel Width | 1250mm / 1550mm | 800-1550mm |

| Panel Length | 3200mm / 4100mm | 2440-6000mm |

| Finished | PVDF Coating | PVDF / FEVE |

| Tolerance | ||

| Thickness | ± 0.2mm | |

| Width | ± 2.0mm | |

| Length | ± 4.0mm | |

| Diagonal | ≤ 5.0mm | |

| Warpage | ≤ 5mm/m | |

Special size composite panel is available and subject to quantity requirement.

| Specification | |

| Panel Weight | 5.5 kg/m2 |

| Tensile Strength (ASTM E8) | 4.9 kg/mm2 |

| Elongation (ASTM E8) | 14% |

| Rigidity | 2,400 kNcm2/m |

| Bending Stress | 11,500 lb/in2 |

| Wind Load Pressure Resistance (ASTM E330-84)None Deformation or cracking | 452 kg/m2 |

| Temperature Resistance (ASTM D2246) | – 50°C ~ 80°C |

| Punching Shear Resistance (ASTM D732) | 22 N/mm2 |

| Sound Insulation (ISO 140/3) | Rw = 26 |

| Impact Test (1 kg steel ball with height 500mm) | 2.2 mm ( Dent depth ) |

| Coating Performance | |

| Gloss (ECCA T2) | 15 – 35 units Gardner 60° |

| Pencil Hardness (ASTM D3363 -74) | 2H |

| Color Retention | ΔE ≤ 2 |

| Bending (ASTM D4145) | ≤ 2T |

| Solvent Resistance (ASTM D5402):Boiling Water Resistance (ASTM D3359-B) | ≥ 100 double rub with MEKPassed |

| Salt Spray (ASTM B117) | Passed 3000 hrs |

| Humidity Resistance (ASTM D714-87) | 3000 hrs no blister |

| Acid Resistance (ASTM D1308-87) | Passed |

| Alkali Resistance (ASTM D1308-87) | Passed |

The Vitally Aluminium Composite Panel is easy to fabricate due to its lightness, rigidity and shock resistance properties. The fabrication can be done by using simple woodworking or metal tools.

|

Cutting

It can be cut into all kind of desired shape easily by using saw and plate saw. |

|

Routing

It can be routed using conventional routing machines. The routing process is going through the alumiunium layer and partial of the polyethylene core. It is recommended to left a uniform core material of 0.3 – 1.0mm on the lower cladding sheet to ensure smooth bending. |

|

Bending

Bending: For 4mm vitally panel, the minimum bending radius without routing is 60mm. Bending process is similar to bending of aluminium sheet. The bending can be done using 3-roller panel bender or dies for specify radius. |

|

Riveting

Vitally Aluminium Composite Panel can be drilled using standard drill for aluminium and plastics. Rivets are commonly used to joint the panel to the structural. It is recommended that either aluminium or stainless steel rivets are used. |

|

Welding

Welding for Vitally is possible using electricity warm tool and welding tool. |

-

Protective Film

Vitally Aluminium Composite Panel is protected by opaque protective film. The film is advisable to be removed as soon as installation is done. Do not leave the film on the panel for more than 45days after installation in order to prevent glue residue on surface due to hot and humid weather.

-

Installation Direction

While installing the panel, it is requested to install all panels in one single direction as per printed on protective film. This is to avoid color shade reflection differences among panels. See illustration below:

The panel surface shall be cleaned with clear water only. Diluted mild detergent is allowed if required. For external wall, it is recommended to be cleaned once a year using high pressure water jet. For internal wall, the panel can be wipe using damp soft cloth. Cleaning frequency is subject to the pollution condition.